Introduction

Simply put, a Software-Defined Vehicle (SDV) is an advanced automotive, where a software manage and controls most of the vehicle functionality. From engine performance and braking systems to infotainment and navigation, software orchestrates nearly every aspect of the vehicle. This shift to software-centric design offers greater flexibility and enables more frequent updates and enhancements than traditional hardware-based systems.

But what’s holding back this automotive revolution?

One significant challenge is increasing systemic complexity. As vehicles become more software-driven, managing the numerous software functions and updates becomes increasingly unwieldy. The emergence of new Electrical/Electronic (E/E) architectures further complicates this landscape, necessitating robust systems that can handle this complexity. Additionally, testing and validating millions of lines of software code is a daunting task that requires precision and thoroughness to ensure safety and performance. With product cycles shortening, the pressure to bring vehicles to market quickly while ensuring quality adds another layer of difficulty.

Moreover, the availability of test benches and Hardware-in-the-Loop (HIL) systems is becoming a critical bottleneck as the number of software engineers working on automotive software increases. Automotive companies and OEMs are investing heavily in these systems to validate software in realistic, hardware-interactive environments. However, as the demand for such systems rises, traditional approaches may not scale effectively, especially given the need for cloud-based development to handle the volume and complexity of modern vehicle software.

. By virtualizing the Electronic Control Units (ECUs), developers can simulate and test software in a virtual environment, addressing many of the challenges associated with SDVs. Virtual ECUs are an essential tool for tackling systemic complexity by providing a scalable and flexible software development and testing platform. They enable comprehensive validation of software before it is deployed to physical hardware, significantly reducing the time and cost associated

1. Safe Testing Environment

The Role of Simulators in ADAS and AV Validation

Key Benefits:

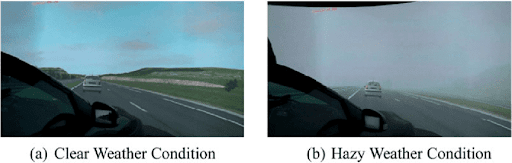

- Risk-Free Testing:Engineers can create and evaluate dangerous scenarios—such as sudden obstacles or extreme weather conditions—without endangering real drivers, passengers, or other road users.

- Controlled Conditions: By eliminating external variables, simulators ensure precise testing, allowing developers to focus on system performance and safety.

- Reproducibility: Simulators enable consistent execution of the same scenario, crucial for verifying the robustness of ADAS and AV systems under varying conditions.

Example:

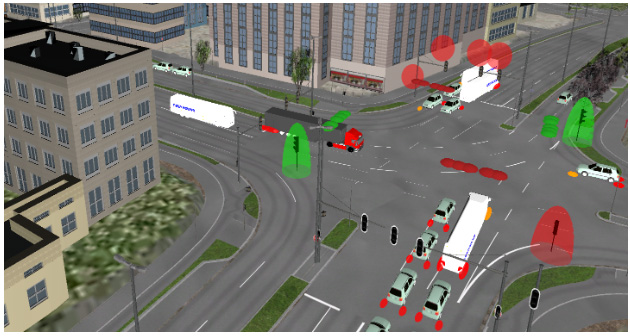

Testing a vehicle’s collision avoidance system in a simulator allows for the safe recreation of sudden pedestrian crossings or unexpected road hazards as shown in Figure 1. This enables engineers to evaluate system responses without real-world risks, providing immediate feedback for rapid refinement.

2. Cost-Effectiveness

The Need for Cost-Effectiveness: Physical testing of ADAS and AV systems involves significant costs related to prototype construction, track usage, and operational expenses. Simulators provide an alternative that reduces these costs while still allowing comprehensive testing.

Key Benefits:

- Virtual Scenario Replication: Simulators can model a wide range of traffic scenarios, from merging onto busy highways to navigating dense urban environments, without the need for physical test tracks or multiple vehicles.

- Reduced Prototype Requirements: Developers can test and refine systems using virtual models, reducing the need for multiple physical prototypes and reducing material and production costs.

- Efficient Resource Utilization: Simulators allow testing numerous scenarios within a single virtual environment, optimizing resource use and reducing overall expenses.

Example:

3. Rapid Iteration and Development

The Need for Rapid Iteration: Developing ADAS and AV systems involves complex algorithms and hardware interactions. Traditional testing methods can be time-consuming and labor-intensive, often requiring physical prototypes and real-world trials.

Simulators address these challenges by offering a dynamic environment where developers can quickly test and refine their systems.

Key Benefits:

- Instant Feedback: Real-time testing provides immediate feedback, allowing developers to observe system performance and make swift adjustments.

- Efficient Algorithm Tuning: Developers can rapidly modify algorithms and retest them if a simulator reveals performance issues, accelerating the refinement process.

- Scenario Flexibility: Simulators can recreate a wide range of virtual scenarios, enabling comprehensive testing without physical constraints.

Example:

4. Comprehensive Scenario Testing

Key Benefits:

- Wide Range of Scenarios: Simulators can model numerous driving situations, enabling extensive testing without physical limitations.

- Adaptability Testing: Simulators recreate extreme conditions to assess how well ADAS and AV systems adapt to unexpected challenges.

- Real-Time Feedback: Immediate feedback allows developers to analyze system performance across different scenarios and make necessary adjustments.

Example:

5. Enhanced Data Collection

Key Benefits:

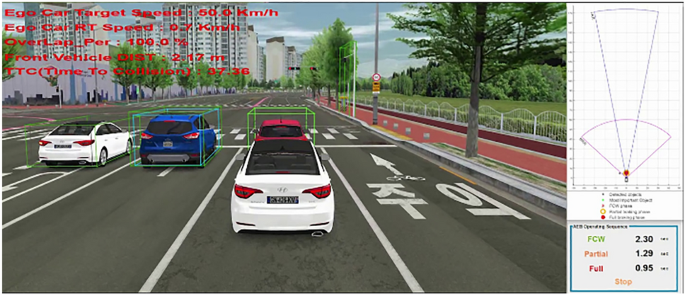

- Real-Time Metrics Tracking: Simulators record performance metrics like vehicle speed, braking distance, and sensor accuracy, offering a comprehensive view of system behavior.

- Performance Analysis: Engineers can analyze data to identify weaknesses and assess the effectiveness of algorithms.

- Informed Improvements: Detailed data allows for precise adjustments and optimizations, improving overall system performance.

Example:

Real-World Applications Across Other Domains

Conclusion

If you’re eager to explore the exciting frontiers of ADAS Validation and Verification and want to learn more about our groundbreaking initiatives reach out to us!

Author